Audio cables, which are an indispensable part of sound systems, have a direct and significant impact on sound quality, rather than just being a connecting element . The clarity, dynamism and accuracy of every note, every instrument and every vocal we hear are closely related to the production techniques of the cables and the choice of materials used . So, how do these seemingly small details affect our audio experience so much?

Material Selection of Audio Cables: The Search for Pure Conductivity

The main task of audio cables is to transmit the audio signal with the least loss. This is directly related to the conductivity of the material used.

Copper: Essential and Reliable Conductor

Copper, the most widely used conductive material, stands out for its affordable cost and good conductivity properties. However, the quality and purity of copper makes significant differences in sound transmission.

Silver-plated copper: brightness at frequencies

Silver-plated copper cables are produced by coating a thin layer of silver on top of the copper conductor. Silver is a better conductor than copper and can further reduce signal loss, especially at high frequencies. This can give the sound a brighter, more detailed, and more open character. However, the quality and thickness of the coating is important; A low-quality coating can lead to problems of oxidation and performance degradation over time.

Sterling Silver: The Address of High-End Performance

Pure silver, one of the most expensive and best conductors, offers unmatched clarity and transparency in signal transmission. The superior conductivity of silver allows even the finest details to be heard and offers a wide dynamic range. However, due to its high cost, it is generally preferred in high-end sound systems.

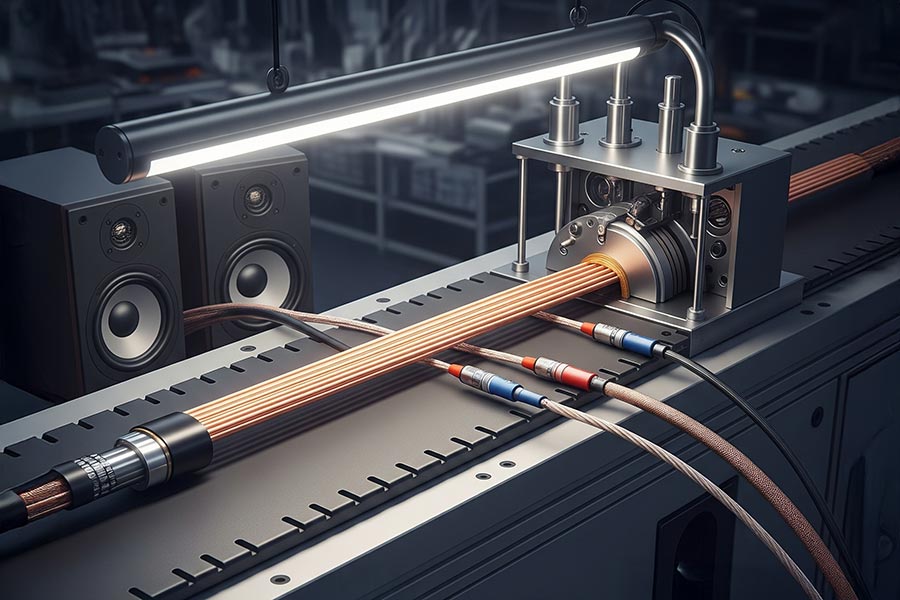

Manufacturing Processes: The Birth of the Cable

As well as the material selection of audio cables, the manufacturing processes directly affect the sound quality.

Wire Drawing: Shaping the Conductor

This process involves passing the metal (copper, silver, etc.) through special molds and turning it into wire of the desired thinness. During the drawing process, the smoothness, uniformity and crystal structure of the wire are of great importance. In high-quality cables, the pull speed and temperature control are optimized to reduce internal stress and achieve a more uniform crystal structure. This minimizes the resistance of the conductor and reduces signal loss.

Insulation (Dielectric) Generation: Maintaining Signal Purity

The insulating material (dielectric) that surrounds the conductor ensures that the signal is protected from external factors and that the conductor is not affected by interference from other cables or the external environment. The most common insulation materials are polymers such as PVC, polyethylene (PE) and Teflon (PTFE).

Outer Jacket Production: Physical Protection and Vibration Reduction

The protective sheath, which is the outer layer of the cables, protects the conductors and insulation material from physical damage (abrasion, bending, etc.). It may also include shielding layers to prevent external electromagnetic interference (EMI) and radio frequency interference (RFI). Different techniques, such as braided shielding or foil shielding, increase the cable's resistance to external noise. The flexibility of the sheath and its ability to absorb vibrations also play a role in preventing unwanted sound distortion, such as the microphonic effect.

The Effect of Production Quality on Sound Transmission: Signal Loss and Sound Distortion

Each stage in the production processes has a direct impact on sound transmission and signal loss.

In conclusion, each stage in the production of audio cables are important factors that determine the final sound quality. Every detail, from material selection to cable pulling techniques, from insulation quality to shielding methods, affects the purity, accuracy and dynamism of the audio signal. To get the best audio experience, it's essential to take care of the audio cables, as well as all the components in the system.