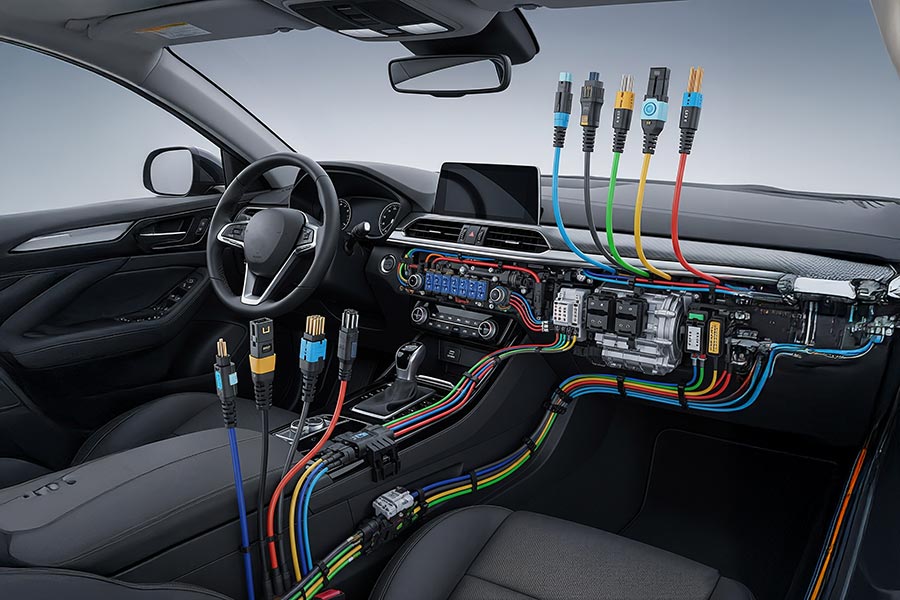

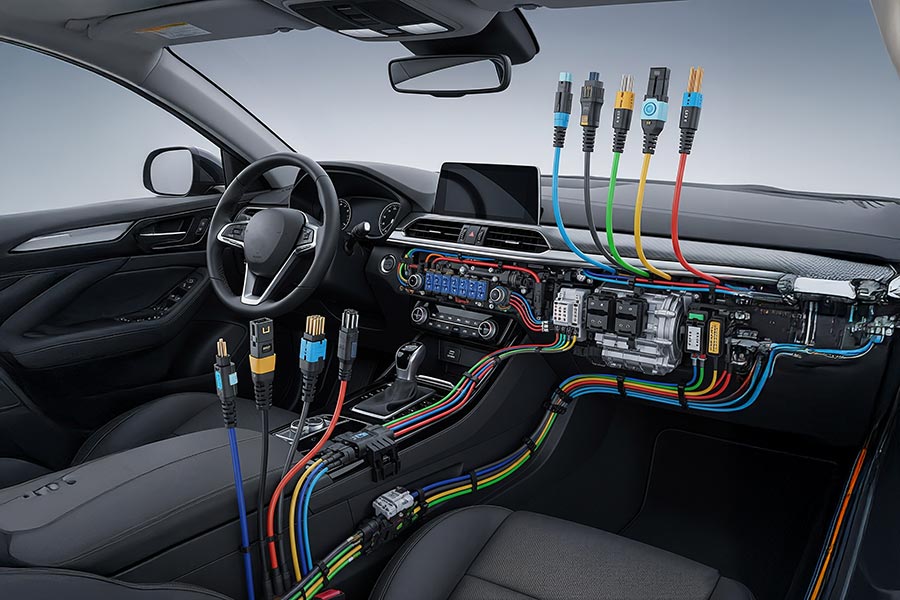

Modern cars have evolved into "computers on wheels" in which complex electronic systems are integrated. The smooth operation of these systems depends on the correct selection and quality of thousands of kilometers of in-car cables that span every corner of the vehicle. These cables, each serving a specific purpose, play vital roles from power distribution to signal transmission, from charging systems to high-speed data communication. The harsh environmental conditions in different parts of the vehicle highlight the technical features and durability in cable selection.

Use of cables in different areas of the vehicle

Different areas of the car present different challenges and requirements for cables:

- Engine Area: Poses a risk of high temperatures, vibration, exposure to fuel, oil, and other chemicals. Cables in this area must have high resistance to heat, chemicals and mechanical stress.

- Underbody: It is exposed to external factors such as water, mud, salt, corrosive substances and mechanical impacts. It is important that the cables in this area provide high protection against water, abrasion and impacts.

- Cabin: Requires precise signal transmission for passenger comfort and safety systems. Aesthetic appearance, flexibility and protection against noise are important for cables in this area.

- Battery Systems (EV/HEV): This region, where high voltage and current-carrying cables are located in electric and hybrid vehicles, has special safety, insulation and thermal management requirements.

In-Car Cable Types and Specifications

1. Low Voltage Signal Cables

These cables usually operate at low voltage levels, such as 12V or 24V, and transmit information/control signals.

- Technical Specifications: It is usually composed of copper conductors with thin cross-sections. Materials such as PVC or XLPE are used for insulation. To reduce the sensitivity of EMI (electromagnetic interference) and RFI (radio frequency interference), some signal cables may have shielding (foil or braid).

- Application Areas:

- Sensor Cables: Data transmission from many sensors such as engine management systems (speed sensor, temperature sensor), ABS/ESP sensors, airbag sensors, parking sensors to ECUs (Electronic Control Unit).

- Control Cables: Transfer of control signals of systems such as lighting (headlights, taillights), wipers, power windows, central locking, air conditioning.

- Instrument Panel and Infotainment Systems: Data transmission to the instrument cluster, radio, CD/DVD player, navigation and speaker connections.

2. High Voltage Power Cables (For EV/HEVs)

It forms the main power transmission line of electric and hybrid vehicles and carries energy between the battery and high-power components such as the motor/inverter.

- Technical Specifications: It has much thicker copper or special aluminum alloy conductors. They are usually coded in orange and indicate a high voltage hazard. For insulation, durable and high-temperature resistant XLPE or silicone materials are used. They may have rugged outer sheaths and shielding that protect against overcurrent and short circuits.

- Application Areas:

- Battery Pack Connections: Mains power lines from the battery to power distribution units (PDUs) and inverters.

- Motor Connections: Power transmission to electric motors.

- Charging System Connections: Connections from in-vehicle charging units to the battery and external charging ports.

- Auxiliary High Voltage Components: Power transmission to high voltage auxiliary systems such as air conditioning compressors, heaters.

3. Charging System Cables

It covers connections from the vehicle charging port to the battery management system.

- Technical Specifications: It can have different cross-sections and insulation properties according to AC (alternating current) or DC (direct current) charging. High current capacity, heat resistance and resistance to external factors are essential. They are generally resistant to frequent donning and removal thanks to their flexible construction and durable outer covers.

- Application Areas:

- In-Vehicle Charging Port Cables: The connection between the charging socket and the in-vehicle charge controller.

- Charging Station Cables: Connecting cables between the vehicle and the charging station (usually sold separately but must be compatible with the vehicle's electrical infrastructure).

4. Data Line Cables: In-Vehicle Networks

In modern vehicles, continuous data exchange between electronic control units (ECUs) and systems is required. This happens through special data communication protocols and cables.

- CAN-BUS (Controller Area Network): It is the most widely used serial bus protocol for in-vehicle communication. It has a simple cable structure consisting of two twisted pair wires. It is ideal for low and medium speed data transmission and enables the exchange of information between critical systems such as engines, brakes, transmissions. It is preferred due to its robustness and fault tolerance.

- LIN-BUS (Local Interconnect Network): It is a simpler and lower cost protocol than CAN-BUS. It is often used for less critical and low-speed applications such as door locks, window motors, seat adjustments, etc. It can have a single-wire or twisted pair cable structure.

- FlexRay: It is an advanced protocol that offers higher bandwidth and real-time capabilities. It is especially used for critical systems such as chassis control, active suspension and steering. It requires twisted pair and usually shielded cables.

- Automotive Ethernet: It is the newest and fastest in-vehicle network protocol. With the capacity to transmit data at gigabytes per second, autonomous driving is indispensable for advanced ADAS systems, high-resolution cameras, and comprehensive infotainment systems. Shielded twisted pair cables are used. It offers high immunity to EMI and low latency.

Result

In-car cables are the unsung heroes of modern cars. Each of them is specifically designed and manufactured to perform a specific function. Covering a wide range from power distribution to complex data communications, the correct selection, installation, and quality of these cables directly impact a vehicle's safety, performance, reliability, and overall user experience. As the automotive industry evolves towards electric and connected vehicles, cable technologies will continue to evolve in keeping pace with this revolution.